Tolerance & Range Technical Information

BS EN771-1 requires dimensions of clay bricks to be declared by the manufacturer in millimetres for length, width and height. Additional to this information, the manufacturer must state the tolerance categories that the mean values of these dimensions fulfil. The tolerance criteria are illustrated below:

- T2 – Smallest deviation from stated dimension.

- T1 – Largest deviation from stated dimension.

- Tm – Manufactures declared deviation from stated dimension (This is at the manufacturers discretion, typically declared by batch, and may be closer or further away from the stated dimensions than the other categories).

The tolerance of the product is the difference between the stated work size and the mean average actual size.

If there are any concerns regarding tolerance of the bricks being used on a construction site the product data sheet should be reviewed to establish which tolerance the product has been supplied to.

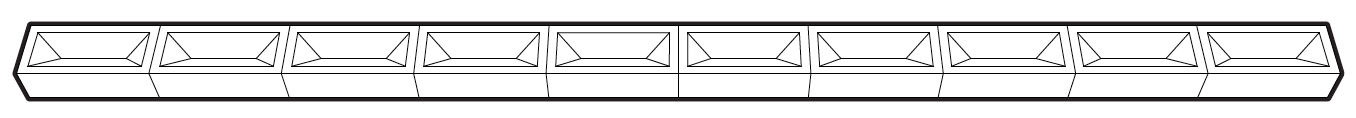

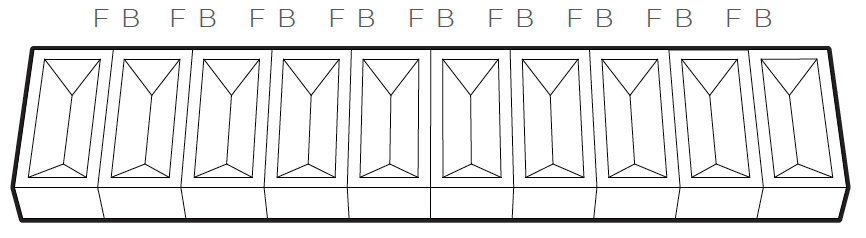

Once the product tolerance category is confirmed, 10 bricks should be sampled randomly from a minimum of 6 packs where possible to conduct a site tolerance test. To ensure a fair test is carried out, all surplus material, such as small particles of clay adhering to the faces of the bricks or blisters should be removed. Respective to the dimensional tolerance that is of concern, place the bricks on a stable flat surface butting each brick uniformly together in a straight line as illustrated in the below diagram ensuring that the bricks are all laid in the same orientation, NOT alternating.

The measurement from the outer edge of the 1st brick to the outer edge of the 10th brick is to be taken using a tape measure, noting the result to the nearest millimetre of the full measurement of all 10 bricks. This figure is to then be divided by 10 giving the mean average of the dimension rounded to the nearest whole mm. This final result must then be compared with the stated figure of the declared tolerance on the product data sheet. The table overleaf illustrates the acceptable dimensions according to the declared dimensions within the respective tolerance categories to confirm whether the bricks you have measured are in or out of tolerance.

LENGTH Arrangement A – Faces forward

(frog up if applicable).

Length measurement to nearest round mm.

Divide by 10 rounding to the nearest whole mm

WIDTH Arrangement B – Face to back

(frog up if applicable).

Width measurement to nearest round mm.

Divide by 10 rounding to the nearest whole mm

HEIGHT Arrangement C – Faces up

(frog to one common side, if applicable).

Height measurement to nearest round mm.

Divide by 10 rounding to the nearest whole mm

The tolerance on height for 73mm products is the same as for T1 and T2 on 65mm.

| Declared Size (mm) | T1 Lower & Upper (mm) | Tolerances (mm) | T2 Lower & Upper (mm) | Tolerances (mm) |

| 40 | 37 – 43 | ± 3 | 38 – 42 | ± 2 |

| 50 | 47 – 53 | ± 3 | 48 – 52 | ± 2 |

| 65 | 62 – 68 | ± 3 | 63 – 67 | ± 2 |

| 68 | 65 – 71 | ± 3 | 66 – 70 | ± 2 |

| 73 | 70 – 76 | ± 3 | 71 – 75 | ± 2 |

| 80 | 76 – 84 | ± 4 | 78 – 82 | ± 2 |

| 90 | 86 – 94 | ± 4 | 88 – 92 | ± 2 |

| 100 | 96 – 104 | ± 4 | 97 – 103 | ± 3 |

| 102 | 98 – 106 | ± 4 | 99 – 105 | ± 3 |

| 190 | 184 – 196 | ± 6 | 186 – 194 | ± 4 |

| 210 | 204 – 216 | ± 6 | 206 – 214 | ± 4 |

| 215 | 209 – 221 | ± 6 | 211 – 219 | ± 4 |

| 225 | 219 – 231 | ± 6 | 221 – 229 | ± 4 |

| 227 | 221 – 233 | ± 6 | 223 – 231 | ± 4 |

| 240 | 234 – 246 | ± 6 | 236 – 244 | ± 4 |

| 270 | 264 – 276 | ± 6 | 266 – 274 | ± 4 |

| 275 | 269 – 281 | ± 6 | 271 – 279 | ± 4 |

| 290 | 283 – 297 | ± 7 | 286 – 294 | ± 4 |

RANGE VALUE

Range tolerance is the difference between the dimensions of the smallest & largest samples taken. To test this accurately, 10 bricks, randomly chosen from a minimum of 6 packs where possible, must be measured individually (length, width or height). The results of the lowest & highest measurements noted for each declared dimension from the 10 brick sample should not exceed the range figure stated in these tables.

Any information published by Bespoke Brick Ltd, including the instructions within this document are understood to be accurate at the date of creation. They are strictly for guidance and Bespoke Brick Ltd accepts no liability in relation to their use or for any losses, however they might be caused. It is your responsibility to take every reasonable step to ensure the use of our product conforms to all relevant health and safety requirements. If you are uncertain in any way, please seek the advice of the appropriate and qualified persons.

All products sold by The Bespoke Brick Company Ltd. are sold subject to our T&Cs of sale. These conditions can be requested from us on 01634 707707, or email [email protected]

| Declared Size | mm | 40 | 50 | 65 | 68 | 73 | 80 | 90 | 100 | 102 | 140 | 190 | 210 | 215 | 227 | 240 | 270 | 275 |

| Lower Limit | R1 | 4 | 4 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 7 | 8 | 9 | 9 | 9 | 9 | 10 | 10 |

| Upper Limit | R2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 |

Long Format

| Declared Size (mm) | Tm Lower & Upper (mm) | Tolerances (mm) |

| 40 | 37 – 43 | ± 3 |

| 100 | 96 – 104 | ± 4 |

| 115 | 111 – 119 | ± 4 |

| 290 | 284 – 296 | ± 6 |

| 327 | 320 – 334 | ± 7 |

| 490 | 481 – 499 | ± 9 |

| Declared Size | mm | 40 | 100 | 115 | 290 | 327 | 490 |

| Declared Limit | Rm | 4 | 5 | 6 | 8 | 9 | 13 |

HOW CAN WE HELP?

Contact our experienced team today to discuss your project in more detail